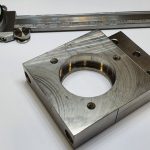

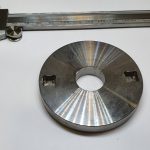

Manufacturing of CNC milled parts

The production of milling parts is one of the main focuses of our daily work, along with turned parts. Several machining centers are available with the most diverse contours can be produced economically.

Depending on the complexity, turned parts are also reworked on the machining centers.

Dimensional range:

Max. travel: 700x400x330 (maximum dimensions, varies depending on machine).

Materials:

Aluminium, stainless steel, steel, brass, plastic, special materials.

Manufacturing systems:

We manufacture our parts in various multi-axis machining centers (CNC 4-axis / 5-axis-

machining centers).

Compared to conventional 3-axis machining, the CNC 4-axis/5-axis machining centers enable us to expect shorter machining times and to achieve a much better surface finish. By using these manufacturing systems we are able to deliver your milled parts in shortest time and best quality.

Machining centers with a 5 axis milling also offer the possibility to create 3D milled parts. In this case it is possible to approach the production piece under almost any angle. This enables the production of parts with highly complex structures and dimensions.

Whether small or large series – we strive to make every product solution possible and will be pleased to provide you with an individual offer for your milled parts.

Equipment for milling parts:

– 1 ROBODRILL vertical machining center – Fanuc

– 1 OKUMA vertical machining center

– 3 HAAS vertical machining centers

– 1 Conventional Milling Machine Center.